Power Generation

Power Generation

Performance Cases

Performance Cases

Power Generation

Power Generation

Performance Cases

Performance Cases

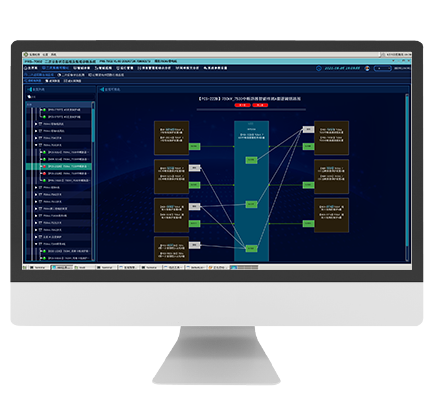

PRS-7002 Secondary equipment state monitoring and intelligent diagnosis system

PRS-7002 Secondary equipment state monitoring and intelligent diagnosis system

Product Description

Scope of Application

Technical Features/Advantages

Based on the SVG vector graphics technology, the visual method is employed to intuitively display the secondary virtual circuit, the process-level optical fiber circuit and the state of secondary equipment originally invisible and intangible, which can fully reflect the operation of secondary equipment and secondary circuits in the station, so that there will be no difference in the operations between intelligent substation and conventional substation.

Based on the multi-parameter identification technology, dynamic self-learning technology and trend identification technology, various identification techniques (e.g.: homologous data comparison, same period data comparison, change trend, mutation monitoring, and over-limit monitoring) are used to make comprehensive judgment of state parameters of secondary equipment, such as temperature, voltage and light intensity. As a result, hidden faults of secondary equipment can be identified automatically, and early warning of hidden dangers of equipment can be provided.

Based on the expert system, the fault of secondary equipment can be quickly located. According to the fault proof table, fast positioning of fault in the secondary virtual circuit and the tripping & closing circuit can be achieved, and corresponding auxiliary decision can be provided, so as to greatly reduce the time required for artificial fault positioning.

By utilizing the intelligent inspection technology, the system can interact with robot and smart screen cabinet, so as realize comprehensive automatic inspection and special inspection of the internal state and appearance of the equipment The inspection report can be sent to the main station, and the inspection results can be automatically compared, alerted and prompted. In this way, the professionalism and comprehensiveness of inspection work can be improved, and the inspection mode can be transformed from station to remote.

The intelligent security measures and technology is employed to enhance the professionalism and comprehensiveness of security measures in intelligent stations via auxiliary means such as automatic ticketing, invoicing, rehearsal, execution and verification. As a result, it can eliminate omissions and out-of-order problems in the implementation of security measures, and improve the operational security.

The power grid fault analysis technique can be used to analyze and present all protection actions in the station when there is failure in power grid, including protection action briefing and power grid fault reports.

Specifications/Submodels

|

Acquisition unit specifications |

|

|

Number of fiber interfaces |

6 100Mbpsfiber Ethernet interfaces, 21000Mbpsfiber Ethernet interfaces |

|

Case dimensions |

444mm×88mm×320.2mm(W×H×D) |

|

Normal working temperature |

-10℃~55℃ |

|

Extreme working temperature |

-25℃~70℃ |

|

Storage and transportation |

-40℃~85℃ |

|

Relative humidity |

5%~95% |

|

Atmospheric pressure |

80~110kPa |

|

Case dimensions |

444mm×88mm×320.2mm(W×H×D) |

|

temperature: Normal working temperature |

-10℃~55℃ |